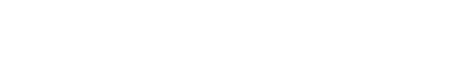

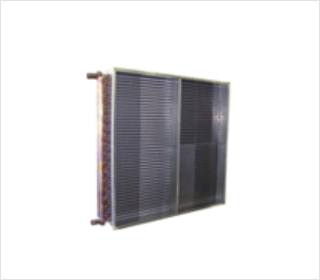

Coils are used in many diverse applications, each having their own unique challenges. Plate or helical style of fin, as well as various tube patterns, allow our coils to easily adapt and meet such challenges.

Plate Fins

Each fin is cut from a sheet of flat material and then punched in a specific pattern that accommodates all the coil tubes. This is similar to stacked sheets of ring binder notebook paper. Over 20 different combinations of tube sizes and center patterns are available.

| Advantages of Plate Fin Coils |

| Low air friction |

Easy to clean/traps less dirt |

| Easy to apply coatings |

Tubes interlocked together |

| Better vibration/tube sag strength |

Wide fin spacing |

| Handle ice/frost build-up |

Tight fin-to-tube bond |

Allows surface enhancements for increased

thermal performance |

Hydrostatic leak test each tube (standard) |

Plate fins are also available with optional surface enhancements.

- Embossed

- Corrugated Wave Pattern

- Sine Wave Pattern

These surface enhancements create different airflow patterns, boosting the coils ability to transfer heat however they also create more air resistance. The key to the coil design is to balance the overall size, fin density, and fin enhancement to achieve the required duty with an acceptable friction loss across the fins that the fan or system can accommodate.

These fin styles and enhancements are available on our basic coil product lines and are also offered on many custom/specialized coils, depending on the tube size and materials required. All coils are pneumatically or hydraulically tested and are available with an ASME “UM” or “U” stamp when required.

With our experience and expertise we can design a coil ideal for your application. We can provide coils with round pipe headers or box tube headers with serviceable cores. We offer copper, carbon steel, and stainless tubes, fins and header materials, as well some exotic alloys. Common applications we service are: high and low pressure, oil coolers, aftercooler, intercooler, hydraulics, blowers, compressors, engines, water/glycol, condensers, evaporators, closed loop systems, and many more.

Have a coil that is beyond repair? Let us help you! We can offer mechanical/performance equivalent of your existing coil.

Click below for additional information or to fill out a request for quotation form.