Circulation & Immersion Electric Heaters

We have industry-leading knowledge in fuel gas/oil conditioning which includes electric heater, filter/coalescer, and control panel design. Each of the key technologies can be optimized for a customer’s specific application requirements, as needed. Many systems are supplied for Class I, Division 2 or ATEX Zone 1 locations. In addition to proprietary design tools, our engineers utilize CFD (computational fluid dynamics), FEA (finite element analysis) and Aspen Hysis process simulation to achieve system results that meet customer needs.

Our systems are designed and manufactured in accordance with a stringent ISO 9001 certified process. Dedicated project teams (applications, engineering, project management, quality, production) are located on a single campus for efficient communication, execution and quick time to market.

We have enjoyed great success with the following types of systems:

- Pressure ratings up to 5000 psi (345 bar)

- Temperature ratings up to 1000°F (540°C)

- Compact and lightweight

- Highly resistant to thermal and pressure shock

- Standard tube-side material is 316 Stainless Steel; shell-side is carbon steel; exotic materials available for both sides

- Bolted or welded shell construction

- ASME “U” stamp available

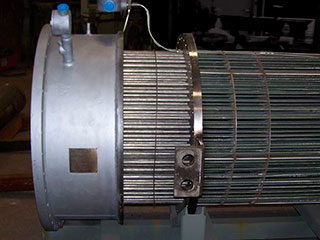

Flanged immersion heaters and circulation heaters are the most common types of electric heaters used in the process industries. Tubular elements are welded into a flange to form the heater. One of the most important criteria for designing an immersion heater or a circulation heater is to choose the proper watt density of the heating elements. The liquid, gas, or solid that you are heating must have the correct watt density to ensure that the heater is safe, properly sized, and have a long life.

We have in stock a large inventory of elements grouped into 10 different watt densities and two power ratings. In fact, with our inventory of elements we can build heaters with any incoming power supply. In reviewing the available stock numbers of heaters, you will find that we have over 5000 standard heater part numbers. Our inventory of heating elements allows us to build your heater in a very short time. We can provide heaters in 3″, 4″, 5″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″, 30″, and 36″ flange sizes, 1″, 1 ½”, 2″, and 2 ½” screwplug sizes and flange ratings from 150# ANSI to 2500# ANSI. By building a pipe body of the same size and rating for the heater flange, we can also provide the circulation heater.